As alloy wheels have become a standard feature in modern vehicles, their aesthetic appeal and structural integrity are essential for vehicle owners. However, rims are prone to damage from curbs, potholes, and general wear and tear. A diamond cutting wheel repair machine is a must-have for auto repair businesses, wheel refurbishing specialists, and car dealerships due to the following benefits:

Precision and Quality – The CNC technology ensures a highly accurate cut, bringing rims back to factory specifications.

Increased Business Revenue – Offering rim repair services attracts more customers and enhances profitability.

Versatility – The machine can work on various wheel sizes and types, making it an essential tool for any wheel repair workshop.

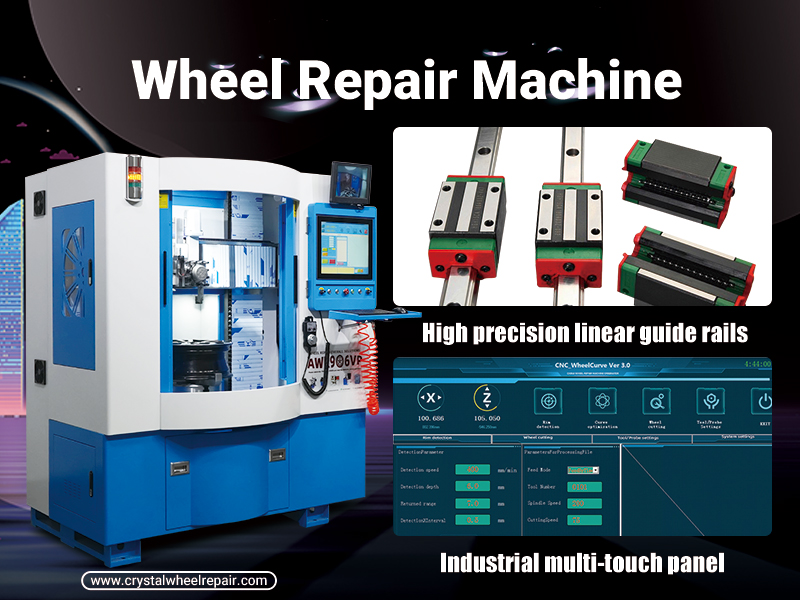

Diamond cutting rim repair machine play a crucial role in the automotive industry, providing high-precision repairs and refinishing for alloy wheels. These machines utilize advanced CNC technology and diamond-tipped cutting tools to restore rims to their original, factory-like condition. With the increasing demand for alloy wheel refurbishment, maintaining these machines is vital to ensure consistent performance, longevity, and cost efficiency.

Regular maintenance not only extends the lifespan of the machine but also enhances safety, reduces the risk of unexpected breakdowns, and ensures the highest quality repair results. Whether you are an auto repair shop owner, a technician, or an industrial user, following a structured maintenance routine will help you avoid costly repairs and downtime. This guide outlines essential daily, weekly, monthly, and yearly maintenance tasks to keep your diamond cutting rim repair machine in optimal working condition.

Cost-Effective Solution – Instead of replacing expensive wheels, repair services using these machines offer a more economical alternative.

So what do you need to do?

Clean the Work Area – Remove debris, metal shavings, and dust from the machine surface. Inspect Cutting Tools – Check the diamond cutting tip for wear and replace if necessary.

Lubricate Moving Parts – Apply appropriate lubricants to guides, spindles, and bearings.

Check Power Connections – Ensure all cables and connections are secure and undamaged.

Wipe the Screen & Controls – Keep the touchscreen and control panel clean for smooth operation.

Tighten Bolts & Screws – Vibration may loosen components over time; check and secure them.

Coolant System Check – Verify coolant levels and top up if needed.

Air Supply System – Drain any water from air compressors to prevent moisture-related damage.

Check Spindle Alignment – Misalignment can affect cutting precision; adjust as needed.

By following this maintenance guide, you can extend the lifespan of your diamond cutting rim repair machine, maintain high-quality repair results, and prevent costly downtime. Regular upkeep ensures efficiency, precision, and overall machine health, keeping your business running smoothly.