Cutting fluid is an industrial liquid which is used to cool and lubricate tools and workpieces during metal cutting. It is an indispensable medium in the metal cutting process. It plays the role of lubrication, cooling, cleaning and rust prevention during machining. A large number of practices have proved that selecting suitable cutting fluid can reduce the cutting temperature by 60~150 °C, reduce the surface roughness of the workpiece by 1~2 grade, reduce the cutting resistance by 15~30%, increase the tool life by 4-5 times, improve the surface quality of the workpiece and reduce the processing cost.

Cutting fluid is an important material for metal cutting. Due to the continuous improvement of manufacturing technology and the continuous emergence of advanced cutting machines, cutting fluid technology has also experienced continuous development. Modern mechanical processing is developing in the direction of high speed, high strength and high precision. With the continuous development of advanced manufacturing technology and the enhancement of people's environmental awareness, people demands a high quality of cutting fluids. Because the cutting fluid generates waste oil during use and is difficult to handle, it causes pollution and damage to the environment and human. In order to meet the requirements of social development, the development of modern cutting fluid has taken a new direction: the development of a high-performance, long-life, low-pollution cutting fluid.

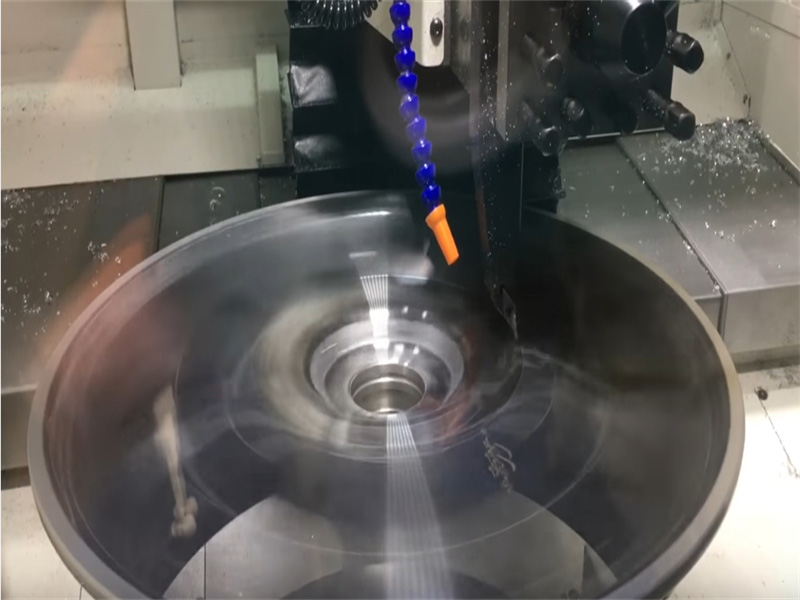

Although the cutting fluid is widely used in metal cutting processes such as CNC lathes and machining centers. For wheel repair machine, a suitable cutting fluid can also be used during the cutting of the wheel, which can effectively reduce the friction between the diamond tool and aluminum chips, the diamond tool and the wheel surface and prolong the service life of the diamond tool. Moreover, the aluminum chips generated during the cutting process are easy to scratch the surface of the wheel, and the cutting fluid can wash away the finely aluminum chips in time, reducing the probability of scratching the surface of the wheel and improving the repairing effect.

In addition, some customers will ask us what kind of cutting fluid to choose. Because of different processing objects, different workpiece materials and processing requirements, there are also differences in the choice of cutting fluid. Because the wheel’s material is mostly aluminum, aluminum is a material that is easy to corrode. Therefore, we recommend that customers choose special cutting fluid suitable for aluminum, which can have good anti-oxidation protection for aluminum surface.

For Taian Crystal wheel repair machine, the cutting fluid is not necessary during the cutting process, only 5% of customers will choose to use the cutting fluid. Because in the process of repairing the wheel, the cutting amount is relatively small, the heat generated is relatively small, and it is not easy to cause the chipping. The most important is that wheel repairing effect has reached the brightness required by most customers without using the cutting fluid.