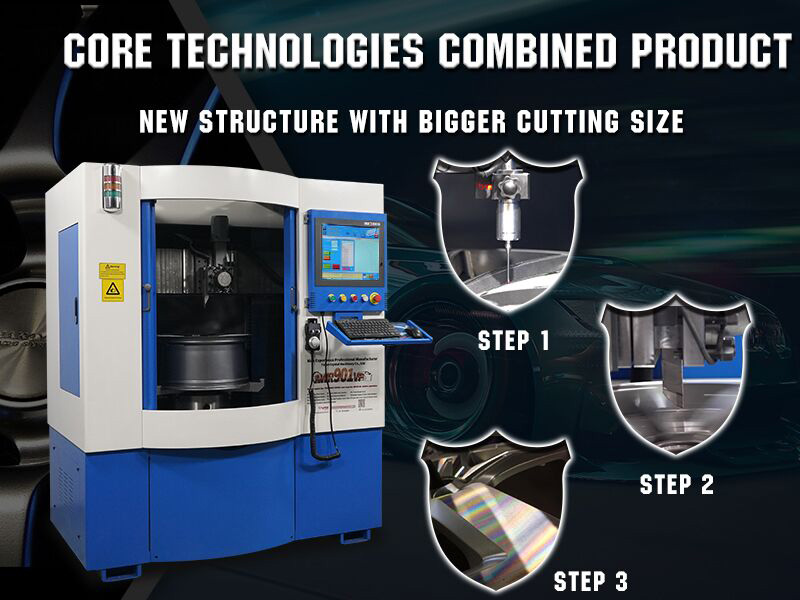

We first brought out our vertical wheel repair machine in 2019, now two years past, the second generation of AWR901VP was ready to step into the market. Crystal independently developed the vertical wheel repair machine, AWR901VP. Based on years of experience in the manufacture, sales and combined with users’ feedback, we have carried out a variety of user-friendly designs. Its floor space is just 1.65m² while the cutting size up to 32’’. Gantry structure, cast iron body, 6 linear rails, electric tools’ holder, multi-touch PC panel, high level consideration of security and automation designs make this machine being one of the most desirable diamond cutting wheel repair machine for wheel repair shop owners. It can realize various repair effects such as mirror finish and different density textured finish etc.

Today, we will describe some highlights of AWR901VP.

1. Arc design with small body.

Independently developed arc design used on this machine, maximum saving the floor space (only 1.65 m²), unrestricted to enter the shop, easy to move and transport, while the maximum cutting size up to 30''. This makes it being the favorite diamond cutting wheel repair machine to the shop owners.

2. Vertical design.

The vertical structure makes it easy to load and unload the wheels. Reduce the difficulty of operation, quick and labor-saving, especially facing with big and heavy wheels.

3. Cast iron gantry structure body.

Cast iron gantry structure body can provide stronger stability and rigidity. Machine weight is bigger, higher cost, so that during the cutting process, the cutter will not be offset by the force generated by the wheel’s rotation, and will not tremble. Even running under high speed, the cutting effect can be 100% guaranteed.

4. High precision linear guide rails.

4 linear in Z, 2 linear in X. A total of six high-quality linear guide rails, higher wear resistance, long service life, easy to replace. Higher precision improves the cutting effect once more, movement is faster improves working efficiency, less noise and environmentally friendly.

5. Full specification electric tool holder.

Exclusive development of one-click switching type electric four-station tool holder. 3 cutters and 1 detection system can be clamped at the same time. Meet the requirements of different users for cutting effects. 2 seconds complete tools’ exchange, accuracy up to 0.005mm, Its experimental use time more than 100000, saves time and effort, fast and high precision.

6. Multi-touch control panel.

17’’ industrial multi-touch control PC panel. Insert with continuous upgraded software of years of research and development by Crystal. Easy to use and learn. Operator without professional lathe knowledge can also be skilled in a short time. Software based on windows, can connect to wifi and support remote assistance.

7. servo motor in spindle.

Equipped with 5.5kw servo motor, higher accuracy, faster response, stronger stability and improves the cutting effect while running.

The use of these mature designs makes the machine a mainstream product in 2021.