In fact, it is the same reason that if the wheel is scratched, the newly bought clothes will become old. But we don't like the old clothes. We can buy new ones anytime and anywhere, but after all, the wheels are so expensive, it is not cost-effective to buy new ones, and it is difficult to buy original wheels. Very bad. Especially if the wheel is scratched, everyone will feel ugly, and they are worried that if the wheel hub is scratched, will it affect the safety?

If the wheel is not seriously scratched, you don't think it is unsightly, so it doesn't need to be repaired. However, if the following situations occur, it is recommended to repair.

1. If the surface of the wheel is severely scratched, it is necessary to repair it. If the scratch is too serious, the aluminum alloy material of the wheel is exposed to the air, and the long-term contact with the air will cause the aluminum alloy material to oxidize. Over time, if the essence of the aluminum alloy is damaged, the wheel will be scrapped and it will be replaced with a new one.

2. The edge of the wheel is severely scratched, similar to the kind of notch, and it needs to be repaired in time. Once there is a gap between the edge of the wheel and the tire, the wheel and the tire are not in close contact, which will cause slow air leakage. Of course, some people will ask if the edge of the wheel is only scratched and there is no gap, and it can be repaired. Of course not, there are scratches even if there is no gap. If your car is parked on the ground, it is inevitable that you will not dream of cats and dogs peeing or something, which will cause the wheel to corrode and eventually cause the wheel to leak slowly.

So to sum up, if the wheel is severely scratched, it is still necessary to repair it. Here, I recommend a method to repair the wheel, diamond cutting wheel repair. Take our company's machine model WRM28H as an example.

WRM28H is a very popular model common rail test bench of our company, and the operation is also very simple, and the old wheels can be refreshed with a few simple steps.

1. Install the wheel

After completing the tool setting and setting of the probe head and the tool, we need to install the wheel on the machine. Through the clamping of the jaws, the hub can be firmly fixed on the chuck.

2. Detect the wheel curve

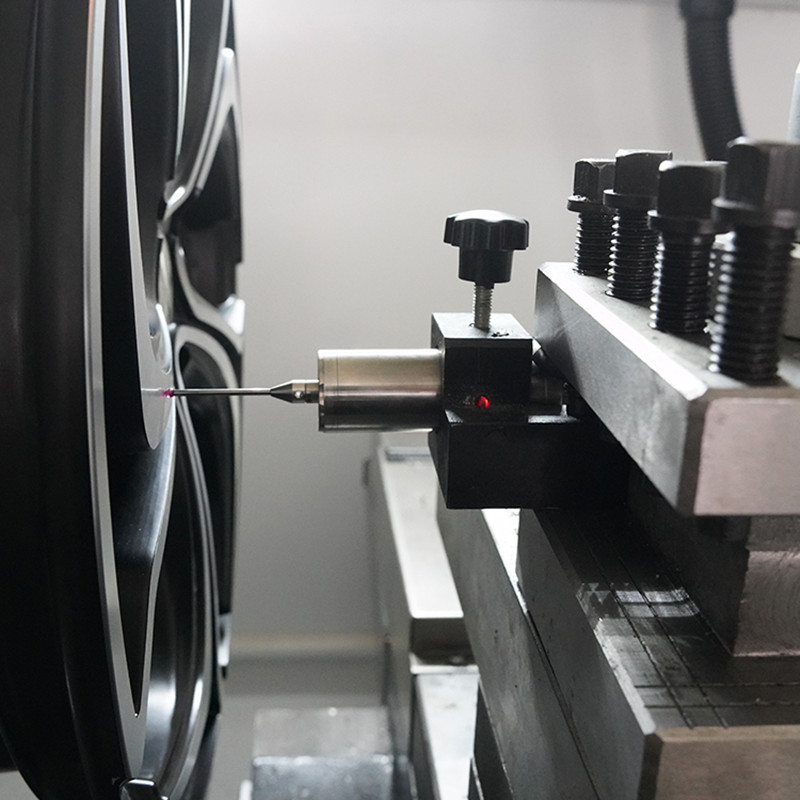

Our machines are equipped with high-precision ruby probes, which can accurately probe the curve of the wheel; for deeper wheels, we also have extended probes available.

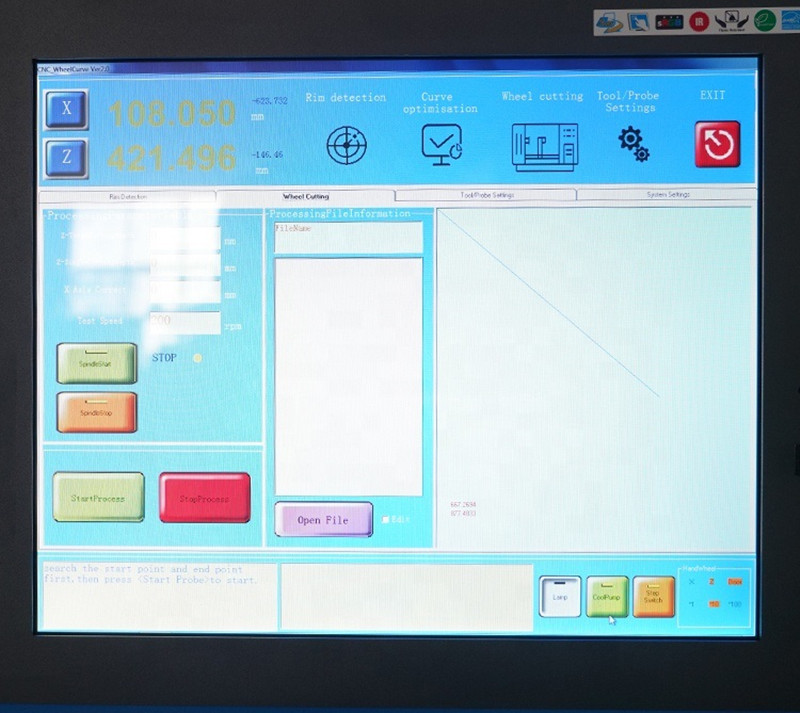

3. Curve optimization

The professionally developed wheel repair software with independent intellectual property rights can automatically optimize the wheel curve, and also support manual modification of program data to realize the repair of various special-shaped wheels.

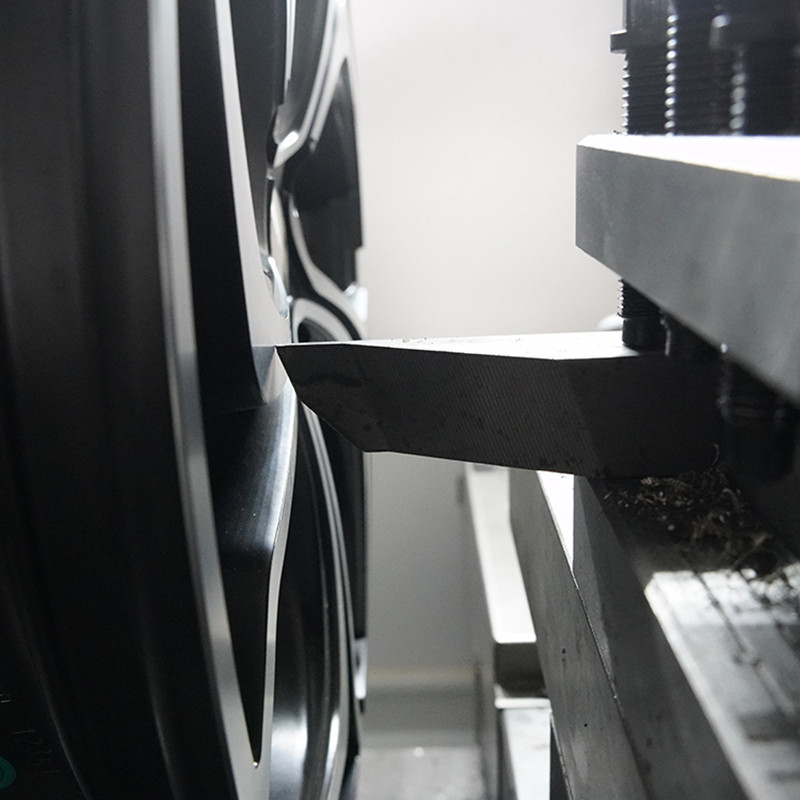

4. Wheel cutting

Through the special diamond cutting tool, the precise cutting of the wheel can be achieved, and the BLINGBLING side of the wheel can be perfectly displayed.

If you are interested in our machines, please feel free to contact us. Taian Crystal Machinery Co., LtdTaian Crystal always waiting for you.