Are you managing a wheel repair shop? Do you feel the fierce competition in the wheel repair service maintenance industry market? With the continuous development of the automotive industry, many car owners are paying more and more attention to personalization. Customize the color and appearance of the car. They have higher requirements for the professionalism of the wheel repair shop. Some wheel repair shop still rely on the traditional grinding machine to manually remove the scratches, but the wheel repair in many developed countries has already moved to the use of advanced automatic wheel repair lathe to repair the scratch damage on the wheel surface. It is equipped with a diamond cutter to make the repaired effect even brighter. Do you know why should use diamond cutting tool?

diamond cutting tool can obtain high machining accuracy and efficiency in high speed cutting. High machining accuracy and efficiency can be obtained in high speed cutting. Good surface finish and precision can be obtained on the workpiece. diamond cutting tool has the characteristics of high hardness, high compressive strength and good thermal conductivity.

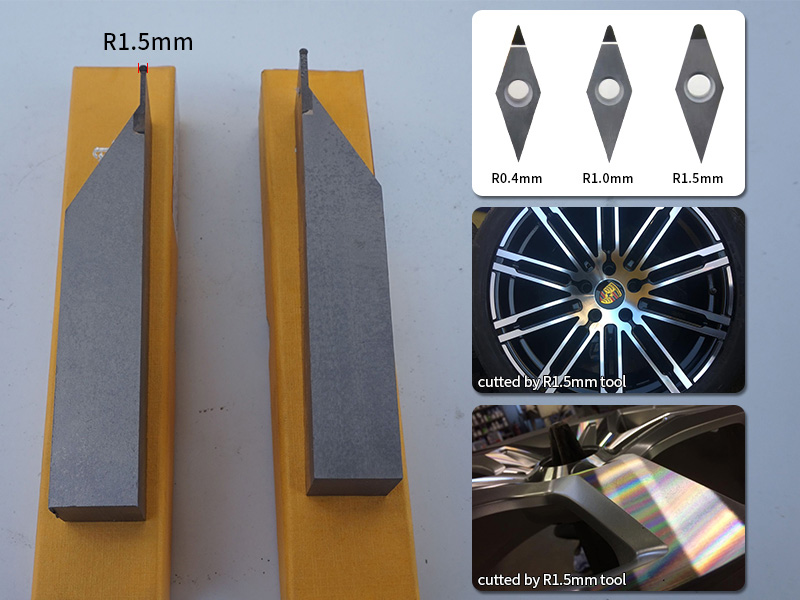

Now that you know the characteristics of diamond cutting tool, Does the diamond cutting tool with different tip diameters affect the wheel repair effect? What kind of diamond cutting tool can realize customers’ different requirement about wheel repair effect ?

1. When R arc is less than 1.5mm, the contact surface between the diamond cutting tool and the wheel surface is small, The requirement to machine performance is not very high. Can achieve the line effect. But it cannot finish great brightness.

2. When the R arc is larger than 1.5mm, the contact surface between the diamond cutting tool and the wheel surface is larger, which requires greater rigidity of the machine and the wheel itself. The cutting effect will be better. But the disadvantage is that the tool will easy to shaker when cutting.

3. When R arc is equal to 1.5mm, Diamond ball head cutter can achieve pre-cutting and post-extrusion in the cutting process, which can ensure higher machining accuracy in high-speed cutting and achieve perfect cutting effect.

Crystal wheel repair machine use special design R-Arc 1.5mm diamond cutters tool, it can achieve perfect line and mirror effect. The larger the R arc of the diamond cutting tool, the larger the contact surface of the machine and the higher the performance requirements of the machine.If the stability of the machine is good enough, the rainbow line effect can be achieved with a diamond cutting tool with a larger R arc. If change to diamond cutting tool with a smaller R arc can also achieve a perfect cutting effect. However, if the quality and stability of the machine tool is poor, the diamond tool with smaller R arc can cut good effect, but change to diamond tool with larger R arc can not achieve good cutting effect. Therefore, diamond cutting tools with different tool tip diameters can achieve different cutting effects. It is also possible to detect the pros and cons of the wheel repair machine. Now you understand how to use the diamond cutting tools?