The quality of wheel repair lathes that are currently on the market is uneven. The form of tool holder is also varied. When customers want to buy wheel repair machine, they are always confused. So what are the different effects of different tool holders on CNC machine?

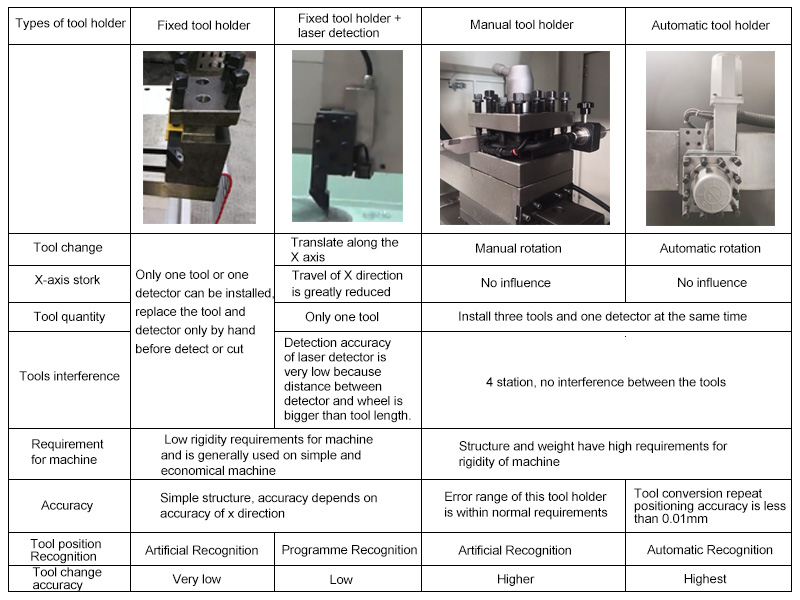

The tool holder is a very important part of wheel repair lathe. It is used to clamp cutting tool. Therefore, its structure directly affects cutting performance and cutting efficiency of the machine. To a certain extent, the structure and performance of tool holder reflect the design and manufacturing level of wheel repair machine. There are different structures for tool holder on current market. They can be roughly divided into four categories, namely fixed tool holder, fixed tool holder + laser detection, manual tool holder and automatic tool holder. Different tool holder types will directly affect the performance of machine and effect of wheel repair.

So do you know the advantages and disadvantages of different tool holders on wheel repair machine?

Fixed tool holder. It has low rigidity requirements for machine and is generally used on simple and economical lathe because of its simple structure and low precision. Only one tool or one detector can be installed (tool and detector cannot be installed at the same time) on fixed tool holder. It is necessary to remove and replace the tool and detector only by hand. The operation is cumbersome, time-consuming and inefficient.

Fixed tool holder + laser detection. This type of tool holder assembly is based on fixed tool holder. Laser detector is mounted on the side of the fixed holder. Only one tool can be installed in the tool holder. The horizontal slide plate is translated along the X axis to complete tool change action. Thus the effective travel of X direction is greatly reduced. The detection accuracy of laser detector is very low because distance between detector and wheel is bigger than tool length.

Manual tool holder. Manual tool holder has four stations. Its structure and weight have high requirements for rigidity of machine. The four-station tool holder can be installed three tools and one detector at the same time. There is no interference between the tools and no influence on X-axis stroke. The error range of this tool holder is within normal requirements and will not affect wheel cutting effect. The tool change efficiency is higher to complete tool change manually.

Automatic tool holder. Automatic tool holder also has four stations. It is rotated to complete tool change automatically and tool change time is shortened. It is the most efficient in these types of tool holders. The computer automatically remembers tool number, very high accuracy and avoiding the misoperation. The tool conversion repeat positioning accuracy is less than 0.01mm.

Through analysis and comparison, the automatic tool holder is the most suitable for wheel repair CNC lathe. Taian Crystal vertical wheel repair machine AWR901VP adopts new electric tool holder to bring you new experience.