The servo motor is an important action element in the servo control system with functions of speed control and position accuracy control. The technology was first officially launched by Rexroth Company of MANNESMANN, Germany, at the HANNOVER MESSE in 1978.

What are the characteristics of servo motor?

1. High control accuracy. The control accuracy of the servo motor depends on the accuracy of the motor itself and the transmission accuracy of the transmission mechanism, accuracy up to 1/1024 per revolution. The accuracy can reach to 0.001mm if the linear displacement is output through the transmission mechanism.

2. Because the servo motor has good low-frequency characteristics and large starting torque, it is very prominent in speed overload and torque overload capability. In torque control mode, its torque will not be affected by the change of motor shaft speed. And the servo motor can be applied to a wider range of applications through speed mode and position control mode.

3. High response speed. Servo motor control performance is more reliable. And the acceleration of its servo system is very superior. The speed is accelerated from standstill to rated speed is very fast, the linkage is good, and there is no delay in executing the command.

4. High reliability. The servo motor uses a superb manufacturing process, so it has good stability and high reliability. It also adopts a unique heat dissipation method, which has good heat dissipation performance, energy saving and environmental protection.

So what role does the servo motor plays on the wheel repair machine?

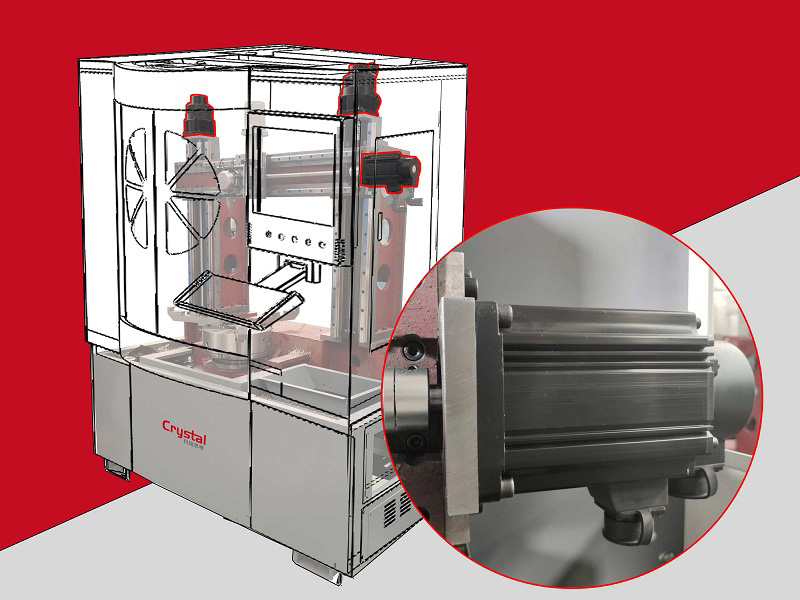

X axis and Z axis require precise control of position and displacement, so we use servo motors to improve the accuracy of the X axis and Z axis. And our vertical wheel repair machines use position control mode, the spindle motor adopts the characteristics of stable low frequency performance: At low speeds, there is no effect on the dynamics of the spindle. Z axis adopts double servo motors, the two servo motors can be perfectly synchronized by complex difference calculation. Due to the precise control of the servo motor, our machine can avoid the occurrence of vibration lines effectively and improve the surface finish when the wheel is repaired. And it can realize various effects such as mirror finish and different density textured finish etc..

In summary, servo motor has high requirements for accuracy and it is suitable for lathe with high efficiency, accuracy, response speed and reliability. CRYSTAL vertical wheel repair lathe AWR901VP equipped with high precision servo motors, which can perfectly restore the original curve of wheel.