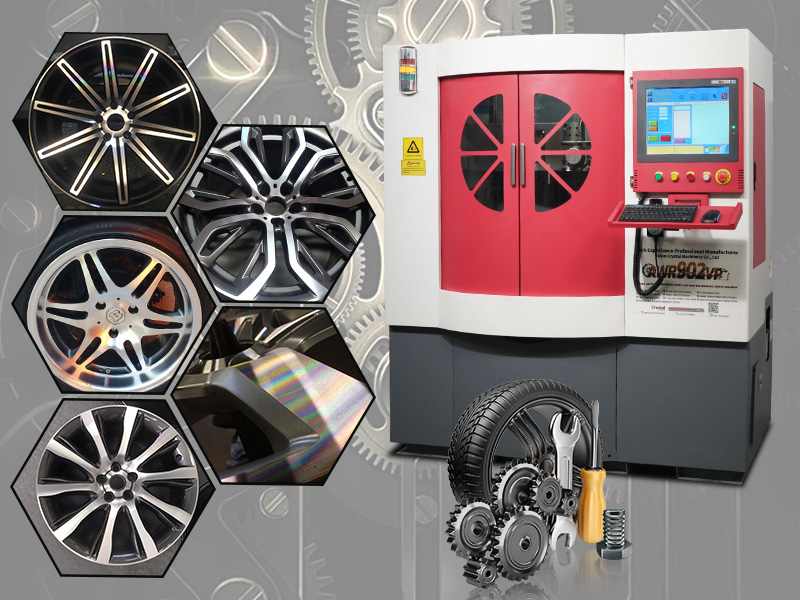

The surface of the wire drawing wheel is very dynamic, because there are fine lines on the surface of the wire drawing wheel, it seems to be many colors, and the surface has a kind of shiny feeling, giving people a pulsating color, dynamic visual effect, the wire drawing effect instantly makes the wheel look high-end, atmospheric, high-grade. Wire-drawing wheels have high added value and are deeply loved by men. The demand for wheels of this kind of craft is on the rise at present, which is the pursuit and love of many young people.

The wheel surface is located outside the car, it is easy to accept the damage from the outside, drawing the wheel is the same, once damaged, it will greatly reduce the overall wheel dynamic, destroy the taste of the trend, for many of the car's appearance is very concerned about the owner, even if there is a little scratch, it is difficult to accept. Then, the surface of the wheel can never be completely undamaged, there are always sometimes, the owner of a car or parking, turning or accidentally hit the wheel, scratch the hub, causing minor or serious damage to the wheel. At this time, the wheel repair is extremely necessary and urgent. For the majority of car enthusiasts, it is necessary for most car owners to have a professional wheel repair enterprise to repair their own wheels. For damaged wire drawing wheels, we use alloy wheel repair machine for professional repair and refurbishment. Repair the finished wheel to ensure that it can reach the factory level.

There are currently two forms of wheel surface repair. One is by polishing the surface of the damaged wheel and then repainting it. The other is to use the wheel repair lathe to turn the surface of the hub. The injured wheel is cut off by a very thin layer of material, so that the wheel can be refreshed. If you like, you don't even need to paint, so that the original cutting lines will be more beautiful after turning.

What are the advantages of using a wheel repair lathe to repair the wheel?

First of all, the wheel repair machine can change the blade grain on the wheel surface by setting different parameters of the machine, and then different effects can appear on the wheel surface after repair. Thin, tight cutting lines will appear mirror effect; The bigger cutting grain will appear obvious cutter grain, can appear rainbow grain, very beautiful.

Secondly, the wheel lathe only cuts less than 1mm of material, which will not affect the structure and safety of the wheel.

Finally, using wheel repair lathes is more convenient and faster. Now our wheel lathes are using intelligent control system, easy to operate, convenient and fast. And the wheel after the repair can choose not to paint, so save a lot of time.

If you are running a wheel repair shop and want to invest in a wheel repair machine, of course choose our most popular vertical wheel repair machine AWR902VP.This machine has high degree of automation, small floor area, simple operation, easy to learn, no need for complex training, and high safety of the machine, effectively ensuring the safety of the operation process and personnel. Wheel repair lathes have their unique advantages for wheel repair. However, as our latest product, vertical wheel repair lathe is also one of our best-selling products in 2020. With a more perfect design and use experience, it has become the leader in wheel repair lathe. New products, automatic equipment is always the pursuit of users and our goals, we hope that our products can provide you with better and longer service.