wheel repair machine is special designed for alloy wheel end-face refurbishment. However, there is an important part in the wheel repair process. The smoothness of cutting motion curve when the diamond cutter along the wheel surface that directly determines the smoothness and cutting effect of the repaired surface.

Crystal wheel repair machine applied this optimization software which can optimize the detected wheel surface curve, so that it can realize perfect wheel repair effect. operation is very simple. Are you interested in learning about it?

1. What is the function of optimization software?

The detection process is mainly to collect points on the wheel surface through the contact detector. By collecting points one by one, the final combination is a tiny line segment rather than a smooth curve. If cutting directly, the final wheel surface will form a number of small steps, wheel surface unable to achieve the mirror effect. How can we turn the tiny lines formed into smooth curves? This is a very important task for curve optimization software to complete.

2. How does optimization software work?

Optimization software working principle: The detection system records the general profile of the wheel by detecting countless points along the radius of the wheel. The optimization software will integrate the contour of the entire wheel and judge the smooth transition mode of arc trajectory between points, Wheel curve is smoothed by complex difference calculation to make perfect transition between each collection point and realize perfect cutting effect.

3. What effect can the optimization software achieve for wheel repair?

The damaged wheel surface curve through optimization, cutting, Make damaged part to achieve a perfect cutting effect, Just like the wheel to do a plastic surgery. Through optimization software to optimize the curve,enables the cutting path of the tool to be very close to the actual wheel end face curve without any influence on the safety of the wheel. By setting the tool feed parameters, can achieve different cutting effect according to customer’s requirements. Such as line effect or mirror effect etc.

Q: If the wheel surface is only partially damaged, Can the entire wheel be perfectly repaired by adjusting the partial cut amount.

A: Crystal optimization software can modify the local curve on the computer, only increase the cutting amount of the partial damaged position, so that the wheel safety is guaranteed, and the realized most reliable wheel repair.

4. Does the optimization software simple to operate?

Yes, this optimization software is very simple to operate. As long as you use the computer, it will be easy to operate the software. In addition, the company has relevant operation training videos for you to learn, without worrying about the complexity of operations.

5. What is the difference between using optimization software and not using optimization software?

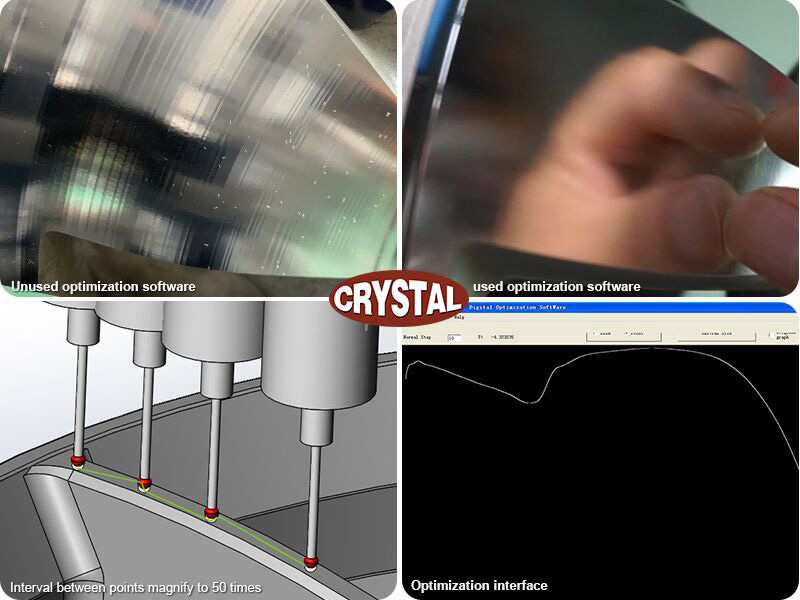

If the detection program not optimize but cut directly, the wheel surface will leave a ring like a tree ring.

On the contrary, the wheel surface after cutting will be very smooth with optimized software and you can achieve the desired effect, such as mirror effect, rainbow line effect or line effect.

Crystal PC version wheel repair machine are standard with the optimization software, simple operation, one key optimization, it is the best choice to achieve perfect cutting effect. If you want the wheel repair machine can achieve a higher repair effect, if your wheel repair machine also need this software, we have a stand-alone version for you to install on your personal computer to use. It will redefine your new standard for the perfect wheel repair cutting effect.