Curb damage is most common for cars, and professional car repairing companies know the best ways of refurbishing car wheels affected by dirt, road salt, and chemicals that lead to finish failure. Oxidation and corrosion are the most common type of damage to aluminum wheels that make the wheels look just too bad.

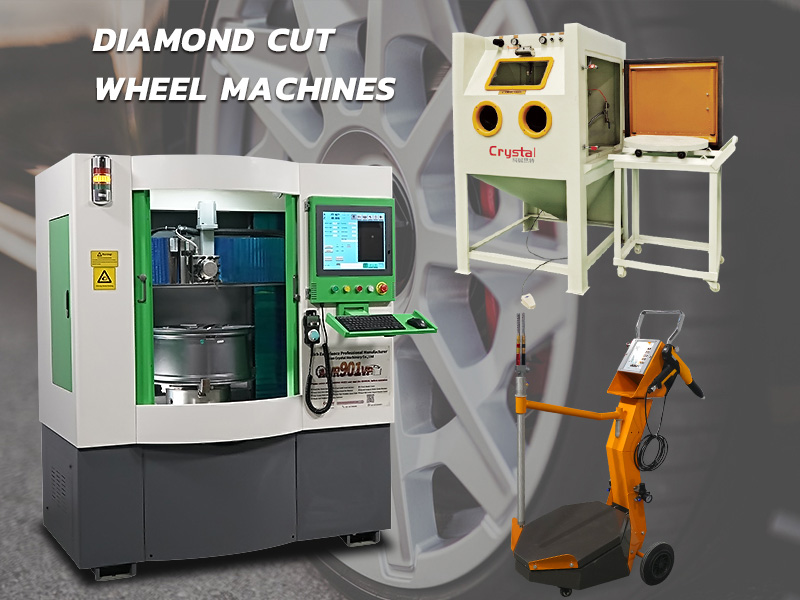

There are many methods of refurbishing wheels to restore its looks and turn the wheels into the highlight of your ride. From cosmetic repair to diamond cutting and powder coating, there are several popular methods of wheel repair. Diamond cutting wheel repair machine provides a long-lasting and superior finish than cosmetic repair or powder coating. The maximum damage to wheels happens on the surface of the wheel that gives unsightly looks that can be set right with the diamond cutting process.

Before you decide to apply the technique of diamond cutting for refurbishing wheels, you must consider some points. The first point to consider is to see if the wheels have undergone some refurbishment before. If it was cut, then how many times did it go through the process? This is important because you can undertake wheel refurbishment for a certain number of times. Professional car repair companies are aware of the limitations in wheel refurbishment and use special diamond cutting machines to cut the minimal metal surface so that there are more opportunities for refurbishment in the long run.

In the initial condition, the wheel surface is so smooth that no protective lacquer can adhere to it unless there is some surface stripping done. During the process of diamond cutting, the wheel is mounted on a lathe machine. As the wheel rotates on the machine, a diamond cutter grazes the surface of the allow to remove a very thin layer that was affected by the stress encountered by the wheel.

By the diamond cutting process , it is possible to prepare the surface for polishing and finishing that enhances the wheel aesthetics, which lasts for a longer time. Applying lacquer to the freshly cut surface protects the wheel for damages for some time.

For the best results, the experts recommend repeating the diamond cutting process 2-3 times. However, it is important not to remove too many layers from the wheel surface, which can become very thin and become vulnerable to cracks and damages.