The role of the wheel is not just for beauty, it is the guarantee of life safety. In the process of daily driving, the frequency of wheel damage is still very high, and almost every car owner faces to this problem. When the wheel is slightly damaged, the cost of replacing the new wheel is too high. The wheel repair effect is obvious and the price is reasonable. It is the first choice for many owners. However, there are many cases that cannot be completed by repairing. Today, combined with the damage range of the wheel and the actual repair process, aluminum alloy wheel damage can be roughly divided into three types.

The first type, mainly based on surface wear and scratch. The second type, deformation and distortion under the action of external force. The third type, a fracture of varying degrees after a strong impact. Among them, the second and third cases are not recommended to repair. As we know, the material of the wheel is aluminum alloy, metal fatigue resistance is relatively poor after deformation by external force, if it is forced to return to its original state by external force, even if the surface has no small cracks visible, from a scientific point of view, the metal structure is completely different with the normal wheel. What follows is the unpredictable occurrence of fatigue cracks and the terrible breaks. It is very dangerous to continue using the repaired wheels.

However, for the first type of damage, the main force structure of the wheel is not affected by repairing the surface, and has little effect on the reliability and safety of the wheel. Moreover, the repair process is relatively simple and mature. So we can choose a wheel repair machine to repair. Specific steps are as follows.

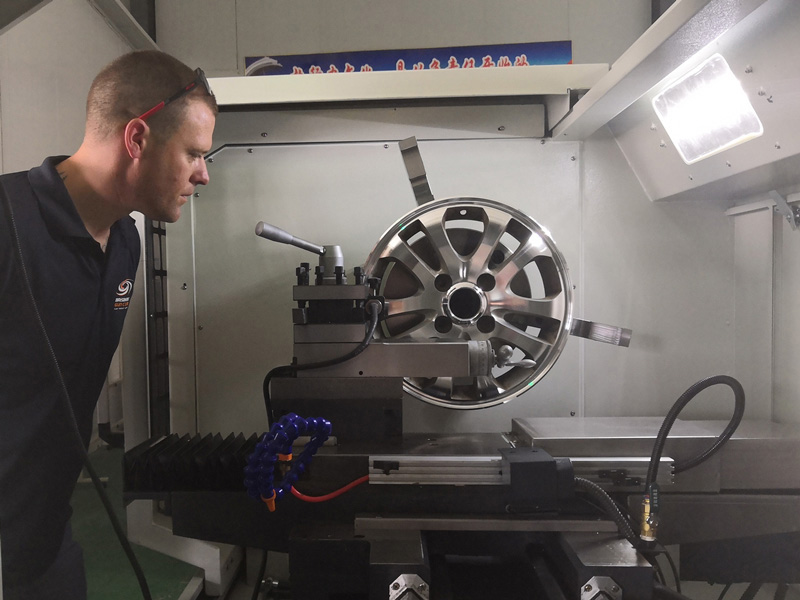

Sandblasting, sanding, filling of the atom, filling the aluminum, polishing, Professional painting, diamond cutting, nano metal protective varnish, fine polishing. These are all the steps for repair a wheel. Let’s focus on the diamond cutting, because this is the most important step and requests the high precision lathe.

About diamond cutting, it needs to use a professional wheel repair machine for precision machining, which requires detecting the surface irregular curvature firstly, and curve optimization, then diamond cutting, because this step will change the thickness of the wheel, so we should choose a wheel repair machine to cut the minimum quantity and achieve the best cutting effect. It is recommended that the repair time is not more than 4 times, if the repair is too much, the support surface of the wheel will be thinner and effects the overall structure.

Some people will ask, where to find such a machine? Don’t worry, Taian Crystal Machinery Co., Ltd is the originator of wheel repair machine in China and has prepared different kinds of lathe models for you. If you have any interest, welcome to inquiry.