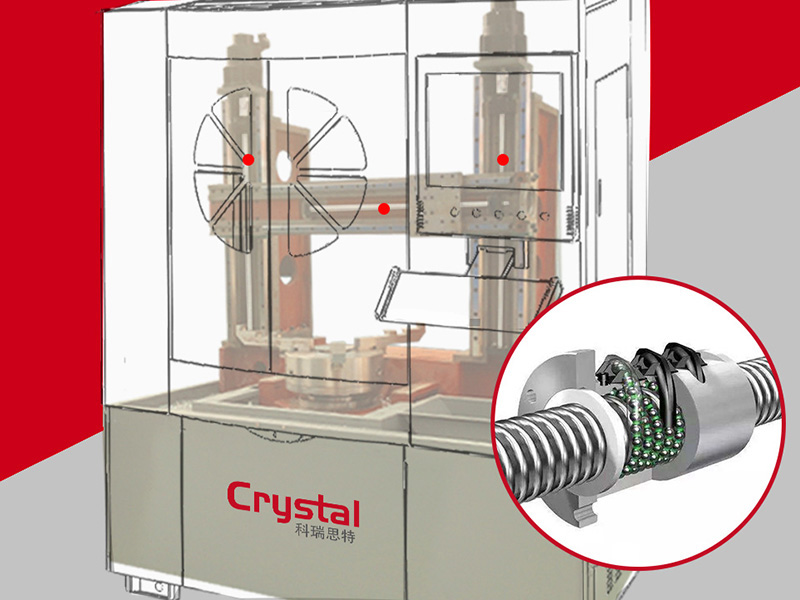

For most customers who repair the scratches on wheel surface, they maybe do not quite understand the importance of the ball screw on wheel repair machine and its structural characteristics to the wheel repair effect. This blog will let us know more about the application of ball screw on Taian Crystal wheel repair lathe.

What are the structural characteristics of the ball screw?

1. High accuracy

The transmission precision of the ball screw is within 0.01mm, which ensures the machining accuracy of the wheel repair machine. The high precision of the machine itself makes that possible to obtain higher positioning accuracy and repeat positioning accuracy in the process of repairing the wheels. This is an important prerequisite for ensuring perfect cutting effect.

2. Stable movement

The ball screw has low frictional resistance during operation and no chattering at start-up, thus ensuring the better stable performance of the wheel repair machine. Stabilization is a must-have performance during wheel cutting, which makes the wheel cutting process smoother. If the stability of the machine is poor, the cutting quality will be deteriorated and the finish will be poor.

3. High transmission efficiency, high durability and reliability

The transmission efficiency of ball screw drive system is up to 90%~98%, which is 2~4 times than the transmission efficiency of traditional sliding screw system. Because of its fast transmission and fast conversion, the cutting time of the wheels is shortened, and the working efficiency is greatly improved. This machine is also equipped with our company's standard automatic lubrication system, it can greatly improve the service life of the ball screw and reduce the failure rate of the wheel repair machine. For the user, there is no need to worry about the use environment and maintenance conditions, the configuration has ensured the perfect effect of repairing the wheels. Is this your ideal wheel repair machine?

The quality of the ball screw will directly affect the performance of the machine tool. Its performance and accuracy will greatly affect the performance and accuracy of its CNC machine, which influences the effect of machining the workpiece. In summary, the quality of the ball screw will directly affect the performance of the wheel repair machine. Taian Crystal wheel repair machine adopts the high accuracy ball screw to ensure the high precision of the machine and ensure the perfect repairing effect of the whole wheel. At the same time, it can complete the repair effect of mirror finishing and different density textured finishing on wheel surface. If you are interested in our machines, please feel free to contact us.