When you are looking for a wheel repair machine, you will find that the detection systems are different used by different manufacturers, and the manufacturers are very good at propagating their detection system is perfect. You deeply aware that the detection system is a very important part of the wheel repair machine, but many customers are little known for these detection systems and do not know how to choose. If you want to buy a diamond cut wheel repair machine, what kind of detection system should you choose? If you are confused like this, I am honored to introduce you to the advantages and disadvantages of different detection systems.

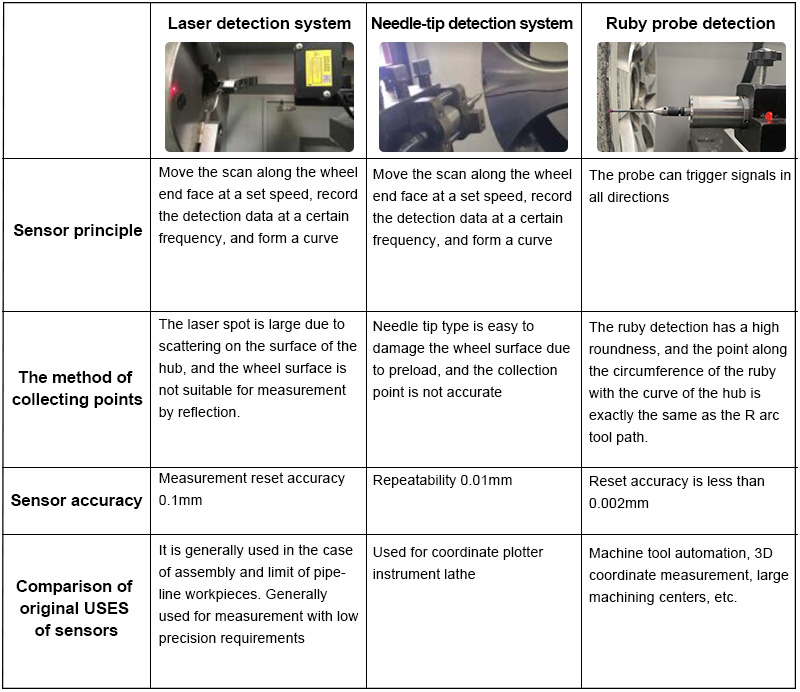

The above is a theoretical analysis of the characteristics of different detection systems in various aspects in the form of a table. In addition, in practical applications, the handling of the more complex alloy wheel surface and wheel edge is more able to test the function of the detection system. How to choose the suit detection system to detect curved wheels, wheel edge and near-vertical deep-dish wheels? The perpendicularity of the laser detection and the surface of the hub affects the measurement accuracy, and the laser scattering error is large, which causes distortion of the collection point and distortion of the curve processing. The inaccurate curve processing of the needle tip detection collection point is more distorted. The ruby collection point is the same as the R tool cutting trajectory, which is closest to the true curve of the hub. The signal triggered by the ruby probe detection system is multi-dimensional, and the 3mm ruby diameter can suit the detection of different shapes of alloy wheels. Therefore, there is no doubt that the ruby probe system is no problem to perform a more perfect detection of complex wheel surface, more difficult wheel out edge and deep dish wheels.

I believe that you have a deeper understanding of the characteristics and differences of different detection systems through the above comparison of the functions and applications about different detection systems. The ruby probe detection system is widely used by the world's leading diamond cut wheel repair machine manufacturers. It also shows that the function and practicality of the ruby probe system have been verified by the market and many customers. The Crystal Wheel repair machine is using the ruby probe detection system which can perfectly detect complex wheel surfaces and wheel edges. The next step of wheel optimization and wheel cutting is made the perfect foundation. Make sure the results of the wheel lathe repair are perfect.