A set of alloy wheels usually shows that you are proud of your vehicle. In addition to bringing a new look to your vehicle, high-quality aluminum alloy wheels can also provide higher performance, grip and turning ability.

However, over time, your wheels may become stained due to daily wear and tear. Worse, potholes can cause cracks, which can greatly reduce performance and cause blowouts. However, there is good news-drivers who encounter problems can use the wheel repair service, the wheel repair machine can repair most aluminum alloy wheel problems.

Why do you need to repair alloy wheels?

There are many forms of damage. Most problems can be repaired, although serious damage may be a safety hazard and requires you to buy new wheels. Most problems fall into the following categories.

Scratches and dents are not a safety issue, but they can damage the appearance of the vehicle. In order to solve this problem, the wheels need to be cleaned thoroughly to remove all surface dirt. Then you can add a professional grinding wheel filler to fill the dents or debris on the grinding wheel. After the filling has solidified, the grinding wheel can be ground to form a flat surface. Paint can be applied to cover up maintenance work.

Wheel bendingis a more serious problem, which can cause the steering column to vibrate and sometimes cause tire punctures. There are several ways to use heating technology and special equipment to straighten aluminum alloy wheels. This process requires expert treatment to ensure that the grinding wheel is perfectly straight and balanced.

Cracks may appear after driving through potholes or curbs. These cracks will gradually increase, thereby preventing the tire from retaining air and causing a puncture. It is important to look for broken wheel repair services to prevent possible safety hazards. The cracks are fixed by welding techniques that incorporate fractures.

The reasons for quick repair of alloy wheels.

Reduce future expenses-cracks will only increase over time. Things that start with minor problems may lead to the need to buy new wheels.

Increase vehicle value-damaged alloy wheels are immediately visible. If you are planning to sell your car, then for a thoughtful buyer, a damaged wheel is an immediate red flag.

Put safety first-bent and broken wheels can pose a danger to you and others on the road. This problem may seem small, but when you least expect it, it can cause more danger.

Improve aesthetics-if you love your car, you don't want to see flaws. Curb rash repair can make your alloy wheels look new again.

Many people choose not to use aluminum alloy wheels in winter, because adding salt to treat ice on the road may cause great damage to the paint and the alloy underneath. Once the transparent protective layer is damaged, the alloy will begin to corrode. Corrosion will produce whitish spots on alloy wheels. Even scratches can cause alloy wheels to begin to corrode.

Corrosion of aluminum alloy wheels is also caused by the reaction between the aluminum alloy and the salt, sand or other deicing substances used on winter roads. If these substances are left on top of the alloy for too long, the wheels will corrode. As the cost of corrosion repair of alloy wheels can be high, it is best to replace the wheels in winter.

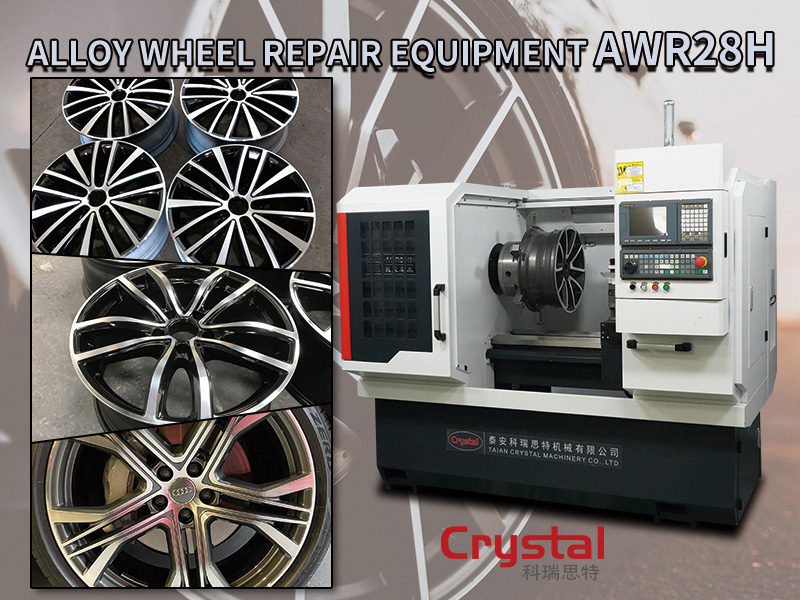

In view of all the above considerations, it is very necessary to choose a good quality diamond cutting wheel repair machine. It can help you repair most wheel problems.

If you also need a wheel repair machine, just contact us.